BJD Crushers has now supplied over a dozen 15x8 Hammermill packages, along with a Flextooth Crusher, to global waste recovery specialist Tetronics International, for plants in Europe, Russia, USA and the Far East.

The crushers are incorporated into Tetronics’ Plasma Arc precious metal recovery systems, which are capable of metal recovery rates of 98% or better, and extract valuable resources from waste such as spent automotive catalytic converters; precious metals found in converters include platinum group metals (PGMs), which are essential for a range of manufacturing process.

The crushers are incorporated into Tetronics’ Plasma Arc precious metal recovery systems, which are capable of metal recovery rates of 98% or better, and extract valuable resources from waste such as spent automotive catalytic converters; precious metals found in converters include platinum group metals (PGMs), which are essential for a range of manufacturing process.

The Flextooth Crusher is utilised for primary reduction of material feedstock, prior to recovery of precious metal content through separation in the plasma system. The valuable metal recovered by the plasma arc smelting process is first cast into sheet form which is then crushed in the Hammermills to a required product size of 30 microns – making it ready for sampling and further processing.

For more information on Tetronics International’s resource recovery projects, click here to view a recent article in Manufacturing Today.

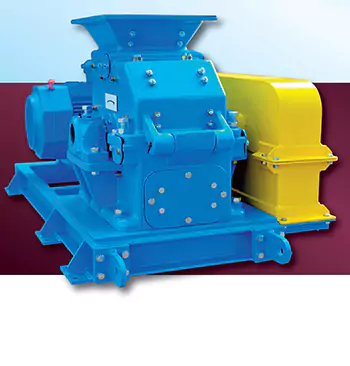

BJD 15x8 Hammermills feature a heavy cast iron frame with heavy-duty renewable liners, and are fitted with a screen arrangement to match the duty. Mounted on a base frame, the modular packages supplied to Tetronics International, comprise Hammermill crusher, fully guarded drive arrangement and 15kW electric motor.

BJD Hammermills have, over the years, acquired an enviable reputation for being reliable, efficient machines for size reduction of friable and fibrous materials. They are part of a complete range of processing and recycling equipment from BJD Crushers Ltd, which includes Impactors, Double Roll Crushers, Mud Hogs, Flexmills and Flextooth Crushers.