A New Chapter for BJD Crushers: A fresh look, new website, and literature

BJD Crushers, one of the UK's leading manufacturers and designers of high-capacity crushing and size reduction machinery for the global mining, quarrying and associated industries, has revealed its exciting

Read more

BJD Crushers set to exhibit at Expo Katowice International Fair 2024

BJD Crushers, designers and manufacturers of crushing and size reduction equipment for over 125 years, will be exhibiting its latest innovations at the International Fair EXPO Katowice, Poland (4-6 September). Martin

Read more

BJD Crushers fulfils major order for crushing equipment to African copper mine

BJD Crushers Limited, the Barnsley-based manufacturer of crushing and size reduction equipment, has recently supplied a major order of its market-leading crushing machinery to a new copper mine and smelting

Read more

BJD Crushers Join West Yorkshire-Based Group Rhodes

Group Rhodes, the Wakefield-based manufacturer of machinery serving the metalforming, composites and heavy ceramic sectors, has acquired Barnsley-based BJD Crushers Limited, a manufacturer of size reduction

Read more

BJD Crushers For Precious Metals Recovery - NEWS UPDATE

BJD Crushers has now supplied over a dozen 15x8 Hammermill packages, along with a Flextooth Crusher, to global waste recovery specialist Tetronics International, for plants in Europe, Russia, USA and the

Read more

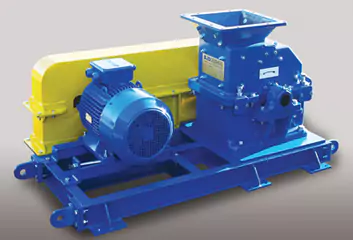

BJD Hammermill For Croatian Fertilizer Giant

BJD Crushers Ltd has recently supplied one of its UEB-type Hammermills to Croatian company Petrokemija d.d., which produces 1.35 million tonnes of mineral fertilizer a year. Based in Kutina, central Croatia,

Read more

BJD Hammermills Pass The Test For RWE

When RWE Power International’s Central Support Laboratories required a second coal crusher for its test lab near to Drax Power Station, North Yorkshire, they opted for a 15x8 Hammermill package from

Read more

BJD Crusher Pitches In At GSB Loams

A BJD MUD HOG crusher has been installed at leading loams and top dressings producer, GSB Loams Ltd., to help process and blend soils for cricket squares and other sports pitches. The Northamptonshire

Read more

Crushing Six For Western Australia

BJD Crushers Ltd, one of the UK’s leading crushing machinery manufacturers, has supplied six BJD Hammermill units for pulverising coal at a new co-generation power plant being built in Western Australia.

Read more

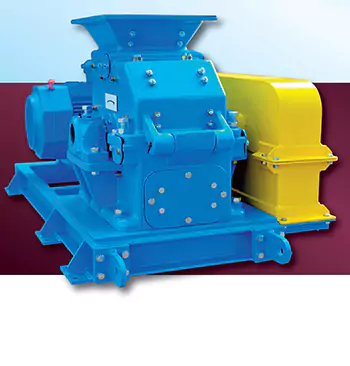

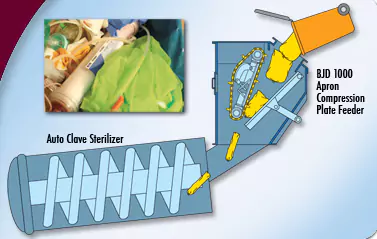

BJD Put The Squeeze On Clinical Waste

BJD Crushers Ltd, the specialist designer and manufacturer of size reduction equipment, has announced the development of an Apron Compression Feeder, designed for volume reduction of waste in-feed material

Read more

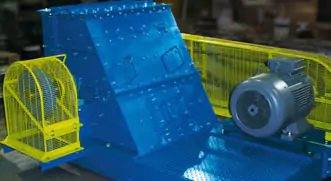

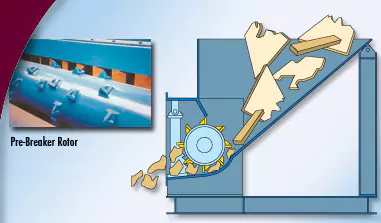

BJD Pre-Breakers For Awkwardly Sized Materials

BJD Crushers Ltd has successfully applied its crushing and size reduction know-how to the problems of primary reduction of irregular and over-sized material by developing the BJD 1500 Series Pre-Breaker.

Read more 15 results.