Understanding Hammermill Crushers and their role in industry

In this blog, we look at Hammermill Crushers, their uses, and why BJD Crushers' Hammermills are among the best in the industry.

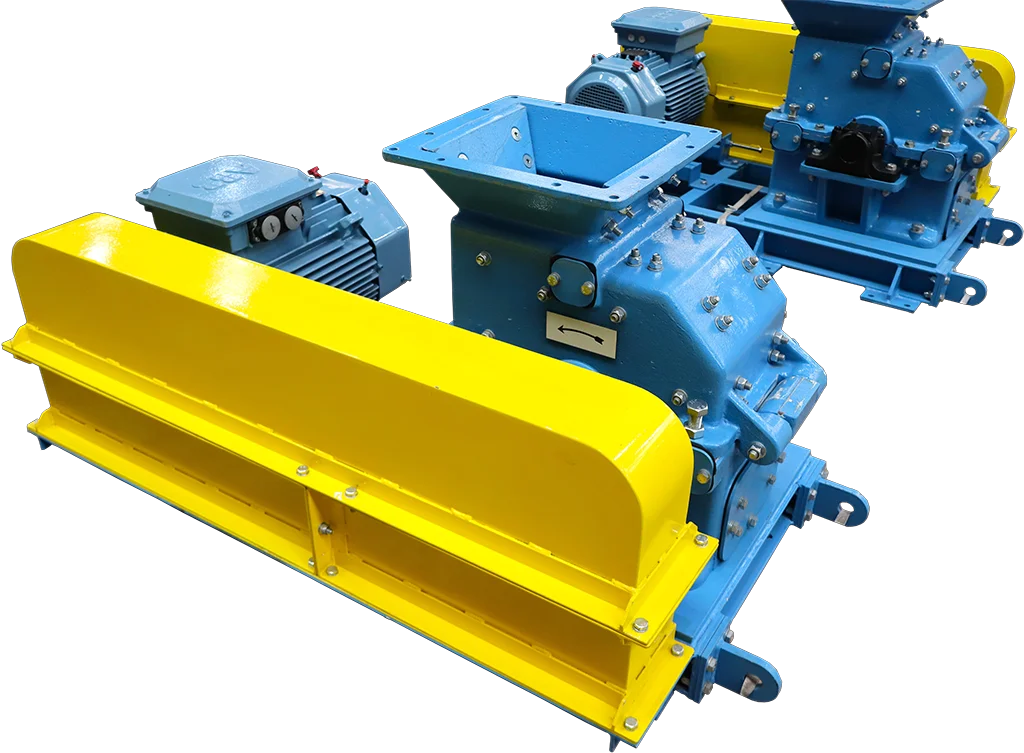

What is a Hammermill Crusher?

Hammermills are essential pieces of equipment in many industries, designed to crush raw materials into manageable sizes, for further processing.

In a Hammermill, material fed into the top of the machine falls directly into the path of the hammers, where it receives a primary reduction in suspension. Secondary impact then occurs in the shatter chamber and against the breaker plate. Final reduction of the material occurs by attrition over the screen bars, where fitted. Any material not reduced to size is recirculated within the mill for further reduction.

When manufactured by BJD Crushers, hammers are made from high-grade cast material or a heat-treated high carbon steel. The machine frames are constructed from cast and fabricated steel and are protected by renewable liners.

Key features of Hammermills

Hammermills offer high reduction ratios, as they can achieve significant size reduction and often produce finely crushed materials suitable for further processing. Features include adjustable breaker plates, which allow operators to modify the output size according to specific requirements.

Where are Hammermill Crushers used?

From limestone, metals, to shale, broken bricks, and plastics, we outline the wide range of applications of Hammermills:

One of their main applications is in the quarrying industry, where Hammermills are primarily used for crushing rocks and aggregates. They efficiently reduce large boulders into smaller, usable sizes for construction and other applications. They are also used for size reduction of grog, clay, shale, and broken bricks and as secondary crushers for materials such as limestone, barytes, bauxite, borax, nitrates, salt, and kaolin.

In the mining sector, Hammermills play a crucial role, where they are used to crush ore and other materials. This process is essential for extracting valuable minerals and metals. In coal preparation plants, they can be used to process coke and shale for stone dusting.

Hammermills are also used in the recycling industry, particularly for processing materials like glass, plastics, and metals, helping to break these materials down into smaller pieces for easier recycling.

In addition, they can be used in the agricultural industry, where they are used to grind feed and other organic materials, ensuring livestock receive properly sized feed for optimal digestion and growth.

BJD Crushers - the original crusher people

BJD Crushers has established itself as a leader in the manufacture of Hammermills, with machines renowned across industry for several reasons.

Firstly, they offer robust design and are built to withstand the rigours of quarrying operations. Their robust construction ensures longevity and reliability, even in the most demanding environments.

BJD Hammermill Crushers offer capacities up to 500 tonnes per hour Crushers

Secondly, they are designed to handle large volumes of material efficiently, with BJD Crushers’ Hammermills offering capacities up to 500 tonnes per hour. This high throughput is essential for meeting the demands of large-scale quarrying operations.

Thirdly, BJD Crushers offers the ability to customise the Hammermill to suit individual requirements. With a number of different models available, BJD allows operators to select the Hammermill Crusher that best fits their specific needs. This customisation ensures optimal performance and efficiency.

BJD Hammermills have a well-earned reputation for being reliable and efficient crushing machines meeting various industrial applications. The machines are ideal for the reduction of friable and fibrous materials, with the ability also to handle moist materials.

Conclusion

Material size reduction is a critical process across many industries, which directly impacts the quality of the final product and the efficiency of subsequent processing stages.

Robust construction ensures lonevity and reliability even in the most demanding environments

BJD Crushers' Hammermills are recognised for their robust design, high capacity, and energy efficiency, making them ideal for meeting the demands of modern quarrying operations.

As industry demands higher quality materials, Hammermill Crushing Machines have a vital role to play in offering high throughput and production efficiency.

For more information visit https://www.bjdcrushers.co.uk/crushers/hammer-mill-crushers